Choosing your PTO percentage: How fast is fast enough?

You need a power take-off, it’s that simple right?

More often than not the process of figuring out exactly what PTO you need can be a very involved task.

One of the most challenging parts of the configuration process is determining how fast of a PTO you need. This is the question that a lot of people get hung up on, and with good reason.

Most PTOs come with multiple speed ratio options. As you can see in the chart below our TG Series and A20 Series have quite the selection.

Behind the numbers

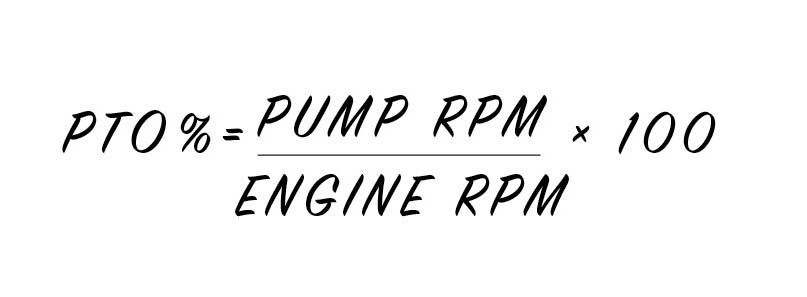

The gear in the transmission that is driving the PTO dictates the exact percentage of the PTO's speed as it relates to the truck on which it is mounted.

Therefore, the same PTO can have two very different actual output speeds on two different trucks even though the truck engines might be running at the same speed. In addition, the needs of what the PTO will be driving can vary significantly, so there’s no way to say use “X” speed ratio code in every scenario.

You must consider the requirements of your truck and truck equipment along with what your PTO will be driving. The kind of equipment you are operating can either be a mechanical or a hydraulic application. The process for selecting your PTO for each kind of application is similar, but let’s take a closer look at both.

Selecting your PTO percentage for mechanical applications

These applications would include (but not be limited to) air compressors, generators, liquid product pumps, dry bulk blowers, vacuum pumps, and more.

The manufacturers of these items provide operating parameters that indicate the input speed that should be provided in order to have proper performance.

For instance, a liquid product pump may come with a recommended input speed of 700 RPM. Once you know the desired input speed of the item being driven by the PTO your next question is to determine the desired engine RPM of the truck when the PTO is being used.

Note: Check to see if the horsepower and torque capacity of the PTO you are selecting is within the operating range required.

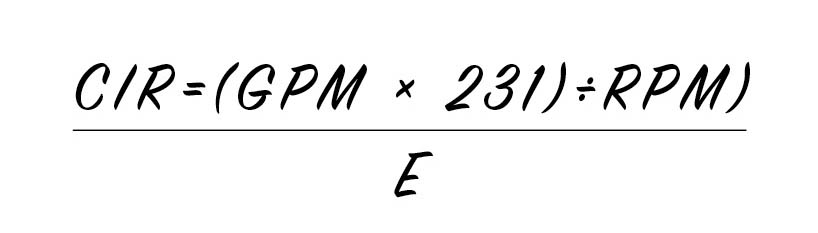

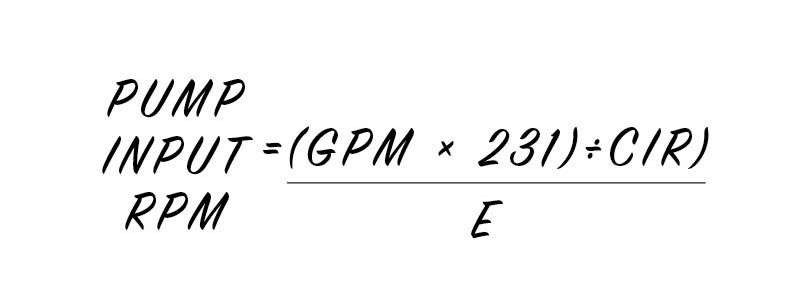

5 steps to selecting your PTO percentage for hydraulic applications

Stay in the range

Hydraulic systems are not perfect; there is a level of inefficiency within every system. As noted to the left, we plan for about 90% efficiency for a brand-new pump. Generally speaking, a hydraulic pump’s efficiency increases as the input RPM increases. In other words, a smaller pump running at a higher speed is typically more efficient than a larger pump running at a slower speed, even though the output flow might be the same. Inefficiency is wasted energy, and that shows up as heat in the system, along with wasted fuel. That’s why you will usually see the recommendation to choose a PTO in the 80%–150% range.

A secondary consideration is that for two pumps in the same frame size or family, the one with a smaller CIR usually will have a higher pressure rating that it can withstand before damage begins to occur. An added bonus is that the price is generally lower for the smaller pump as well.

To save some leg work, we have provided a list of some of the most common hydraulic and mechanical applications and their average flow requirements, PTO speeds, and the most common PTO series used for the given application.

Need more formula help?

We've done the hard work for you. Check out this tool we created to help you calculate your PTO percentage, among other things, quickly and easily.

Ready to build your own PTO?