Help Prevent the Most Common Dump Pump Failure

Muncie Power Products' line of dump pumps is available in a three-line system option to help prevent the most common dump pump failure of high temperatures resulting from the pump being operated too long in neutral.

Muncie Power Products' line of dump pumps is available in a three-line system option to help prevent the most common dump pump failure of high temperatures resulting from the pump being operated too long in neutral.

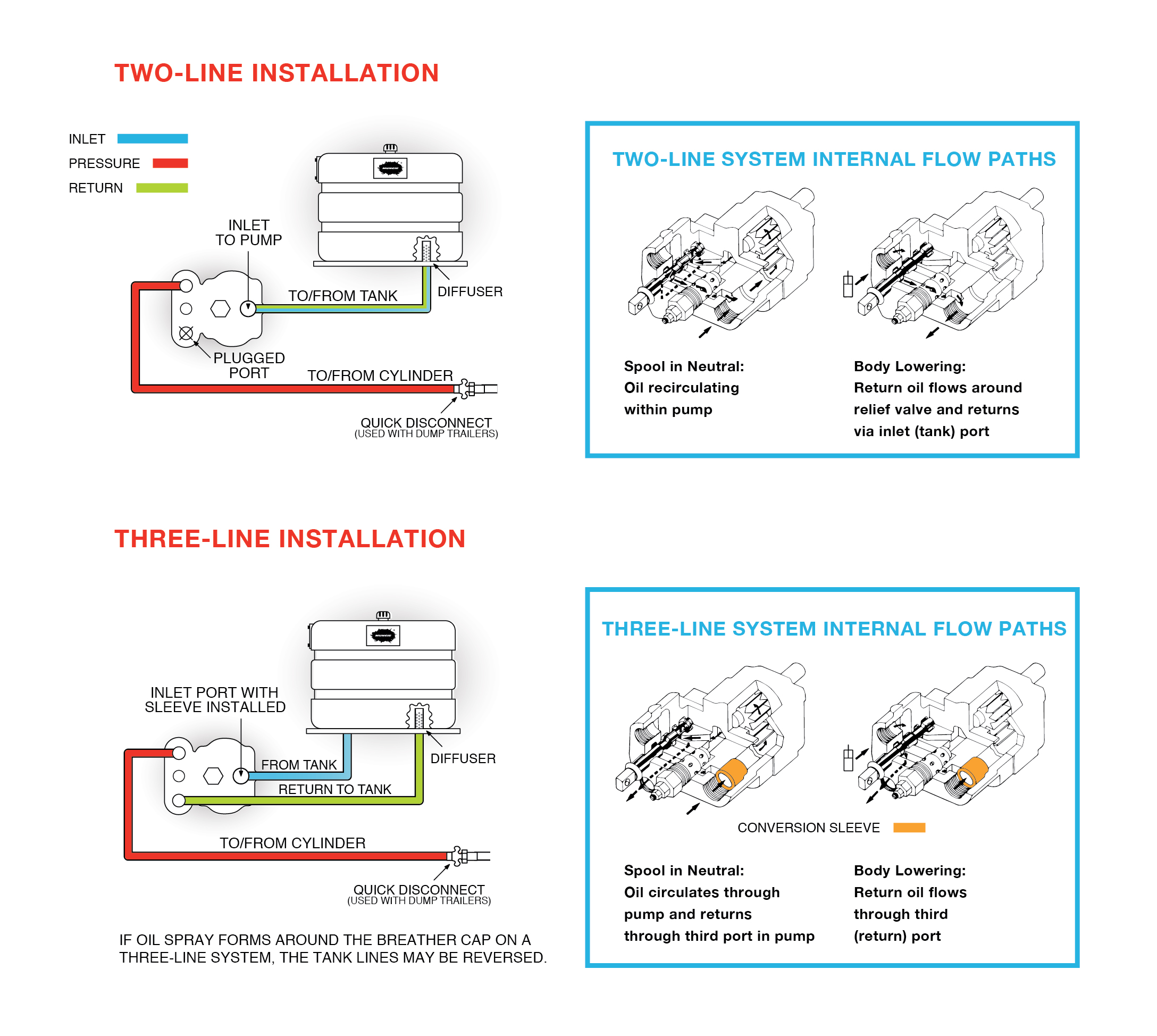

A three-line system includes a separate line to return hydraulic oil from the cylinder directly to the reservoir instead of forcing its way back through the inlet line. The three-line allows faster down cycles and ultimately runs cooler.

Available dump pumps include the E Series and S Series. Both the E Series and S Series are available in the three-line option. Two-line systems are also available. These systems can function effectively, but only if not left operating too long in neutral.

RELATED: Wet Line Kits for Dump Trailers: Two-line vs. Three-line

The E Series has a maximum pressure of 2,500 PSI and is the standard equipment for tandem, tri-axle dumps, and dump trailers with high-volume cylinders. Its pressure-balanced wear plates promote high efficiency. Larger port options for fast cycle times are available with the EH model.

Designed for small single or tandem axle dump trucks, the S Series is available in 6, 11, and 15 GPM at 1,000 RPM sizes. The three-way dump pump valve allows for proper single-acting hoist operation on smaller dump truck applications.