To shift or not to shift

One of the most interesting decisions when choosing a power take-off (PTO) for your application is whether it makes more sense to utilize a constant drive or clutch shift PTO. We often see clutch shift PTOs being the preferred choice on applications such as dump, utility, tow and recovery, and fire trucks; while continuous duty PTOs are often preferred on refuse, street sweepers, and snow plows.

Oftentimes, both PTO options can get the job done well. This ultimately comes down to the application requirements and your preferred system setup.

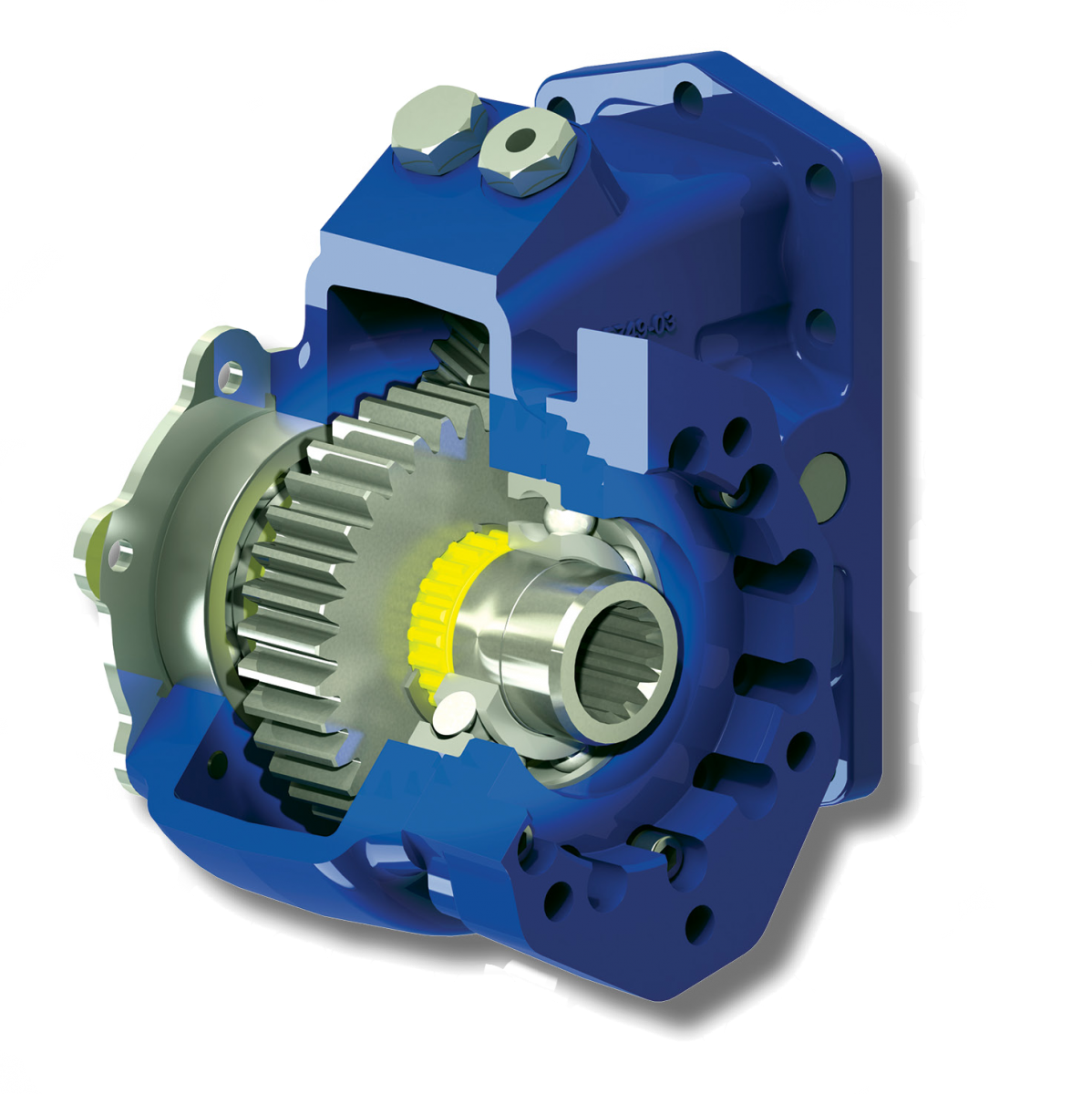

Constant Drive Design

The constant drive PTO is often preferred because of its simple design and generally lower cost. A constant drive PTO is non-shiftable, meaning it’s always engaged and always turning the system. These PTOs are ideal for continuous duty applications, or applications that require numerous stops at a high frequency with duty cycles that last longer.

Constant drive PTOs are also often smaller and lighter, generally leading to an easier installation process. The simple design of these PTOs makes it easier for operators as they won’t have to worry about continually engaging and disengaging the system.

The biggest challenge for these units is the lack of ability to disengage the PTO while it’s not in use. This can be largely overcome by pairing the PTO with a variable displacement pump (VDP) in which you can control flow. Using a VDP, you bring the ability to switch the hydraulic system off and on, although you’ll still have a slight drag on the engine due to the small flow that will be required to maintain system lubrication.

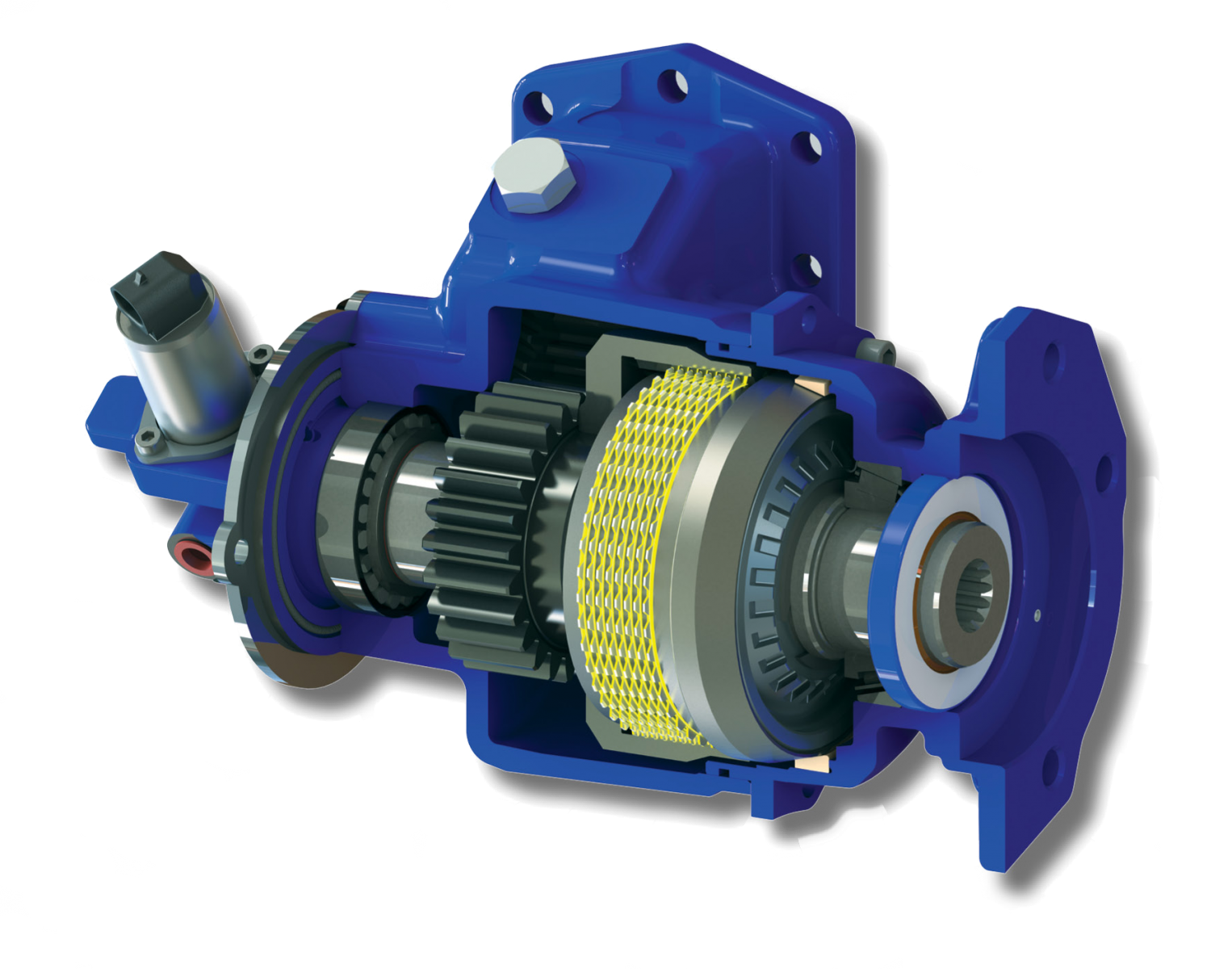

Clutch Shift Design

A clutch shift PTO is often preferred because of the ability to switch the PTO on and off with ease. This allows you to completely disengage the hydraulic system when it’s not in use. This makes the clutch shift PTO ideal for all applications that have an intermittent duty cycle, or cycles that are less frequent and do not last as long.

Clutch shift PTOs have become more common on continuous duty applications. When your truck is not doing work, or you’re between stops, you can disengage the hydraulic system, which in theory will reduce the drag on the engine allowing for fuel savings. While the savings may be relatively minimal, they can add up for large fleets over time. This feature also comes in handy if a hydraulic line gets cut, as you can quickly shut off the PTO and stop the flow of hydraulic fluid, reducing the amount of spill in the environment. For some applications, such as snow plows, a clutch shift unit is able to pair with logic to allow the PTO to be automatically disengaged when needed.

However, the clutch shift PTO does cost more than a constant drive unit, but depending on the type of pump used on the constant drive unit, this could be negligible. A clutch shift PTO may also be more susceptible to wear if the application requires a lot of cycles and can make operators less productive if they need to constantly engage the PTO.