Hydraulic Hose Basics: Types, Laylines, and Pressure Ratings

The work truck industry often takes common knowledge for granted. In this article, we will review types of hydraulic hose, easy ways to understand laylines, and what different hydraulic hose ratings mean.

The main purpose of hydraulic hoses is to allow fluid movement—in this case, hydraulic oil—between two port locations in a hydraulic system. Oftentimes, as an added benefit, hydraulic hose absorbs vibration and noise.

Parts of a hydraulic hose

Inner tube

- Typically flexible

- Allows the transfer of fluid

Reinforcement layer

- Three types: braided, spiral, and helical (typically for suction/vacuum)

Outer layer

- Designed to withstand harsh weather conditions, abrasions, or chemicals

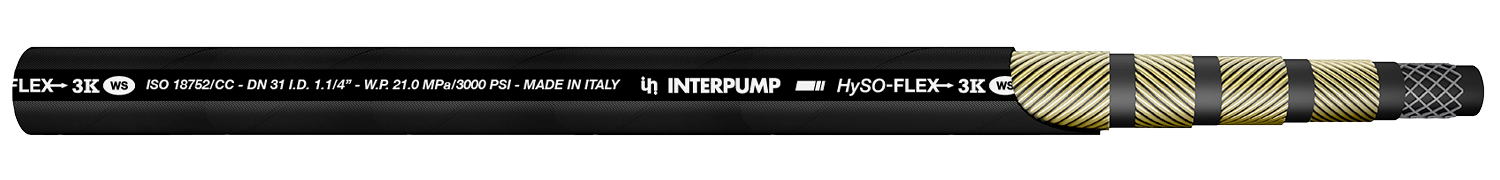

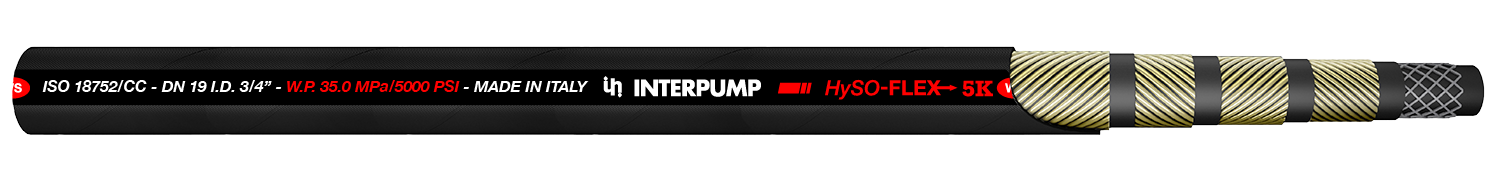

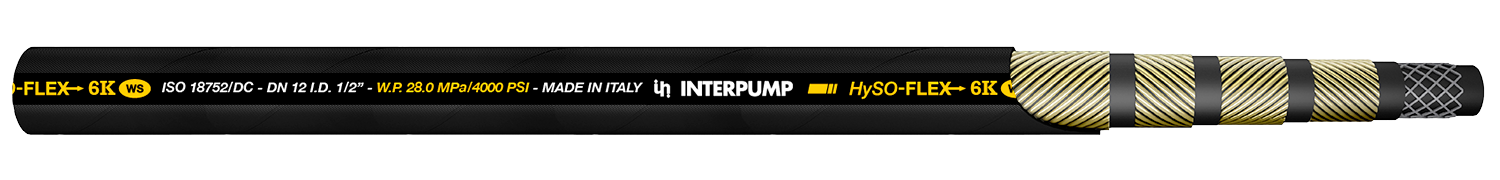

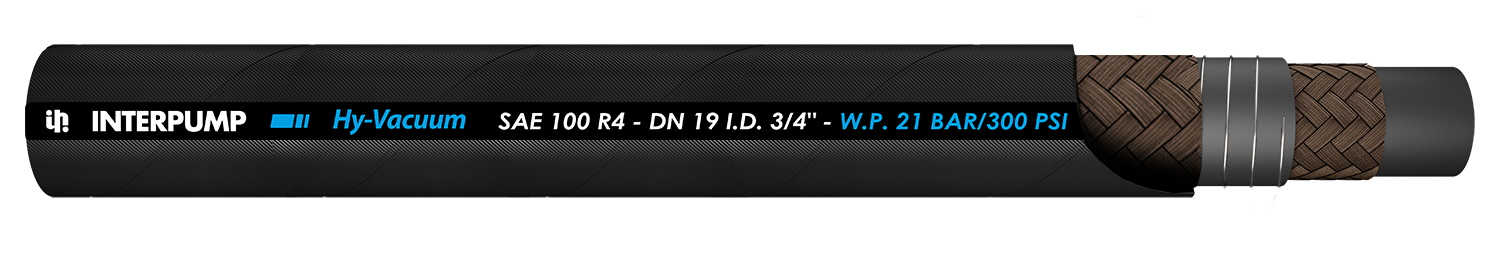

Understanding laylines

The information printed on the length of the hydraulic hose is known as the hose layline. This information includes the manufacturer and/or brand, hose series, construction standard(s), internal diameter, maximum working pressure, and any additional approvals.

How are hydraulic hoses classified by pressure ratings?

Hydraulic hoses can be classified by the pressure they are designed under normal operating conditions: low pressure, medium pressure, and high pressure. Hoses can also be classified by construction/reinforcement type, temperature range, and other performance characteristics.

- Low pressure: Below 250 PSI and most commonly with textile/fabric braid reinforcement

- Medium pressure: Up to 3,000 PSI and most commonly with wire braid reinforcement

- High pressure: 3,000–6,000 PSI with a mix of wire braid and spiral braid reinforcement

Reinforcement types for hydraulic hose

BRAIDED

The braided wire has a crisscross pattern that allows flexibility (these wires sit on top of each other). This type of overlapping braiding of the wire allows for flexibility to make tight bends and significantly improves burst resistance.

Braided hose is the most popular type of hydraulic hose and is available in a variety of sizes and pressure ratings. It is typically designed for medium to high pressures. Applications such as dump trucks, log splitters, snow plows, and farm equipment commonly use braided hoses. However, it is not ideal for high-impulse applications, like rock crushers, where there are severe vibrations that can cause the braids to stretch and separate.

| Type | Description | Muncie Power's offering |

| 1-wire |

|

|

| 2-wire |

|

|

| 3-wire |

|

|

| Textile (1- or 2-wire) |

|

|

SPIRAL

Spiral hose is considered a heavier-duty and stronger hose. It is typically suitable for high-pressure applications as compared to a braided hose. Applications such as mining equipment, earthmovers, oil and gas, and some cranes commonly use spiral hose. This hose also works well with high-impulse applications. The spiral wires are parallel to each other and wound around the hose (these wires appear more layered or stacked evenly on top of each other).

| Type | Description | Muncie Power's offering |

| 4-wire |

|

|

| 6-wire |

|

|

HELICAL

A helical hose is an embedded helically-coiled wire between multiple layers of braided wire or textile reinforcement to prevent the hose from collapsing.

| Type | Description | Muncie Power's offering |

| Helical |

|

|

Inner Diameter Measurement

The inner diameter (I.D.) is measured in inches. The range is typically 1/4"–2" I.D. for hydraulic hoses.

How to select the best hydraulic hose for your work

A common industry acronym, STAMPED, is used to help determine the best hydraulic hose for your application.

Size

This is the inside diameter of the hose, although the outside diameter is also needed when working within a confined space.

Questions to consider: What is the inner diameter (I.D.)? What is the outer diameter (O.D.)? What is the required length?

Temperature

It’s important to know that the chosen hose will withstand the highest temperatures it will be expected to withstand.

Questions to consider: What are the temperatures of the fluid? What are the surrounding temperatures?

Application

This is the application and environment in which the hose will be used.

Questions to consider: What kind of an application? Will the connection points be rotated, dragged, or experience excessive vibrations?

Material

The kind of fluid will be running through the hose.

Questions to consider: What kind of material is transferred? Is it compatible with the tube of the hose?

Pressure

It’s critical to know the maximum required pressure as well as the safety rating to understand the burst rating of the hose.

Questions to consider: What is the maximum system pressure? Is this a pressure or vacuum application? Are there pressure spikes?

Ends

It’s necessary to know the types of ends that will go on the hose, including the thread style and the material.

Questions to consider: What should you look for to ensure quick connect fitment and compatibility (i.e., male or female, angled or straight, JIC thread, metric, etc.)?

Delivery

This is the delivery requirements for the hose.

Questions to consider: Delivery time from the manufacturer? Testing, quality, packaging, etc.

Standards for hydraulic hose

In North America, the typical hydraulic hose standards we use are set by the Society of Automotive Engineers (SAE). Muncie Power Products provides a series of hydraulic hose standards in the 100R Series, defined under SAE Standard J517.

In Europe, there are two main standards: the International Standards Organization (ISO) and the European Norm/Standard (EN). These ISO and EN standards are also growing in popularity in North America.

If you have additional questions, please call our customer service team at 844-745-6335.