Understanding the Importance of Minimum Bend Radius in Hydraulic Hoses

Hydraulic systems are the backbone of numerous industrial applications, powering everything from heavy machinery to precision equipment. Ensuring the efficiency and safety of these systems requires attention to detail, including understanding the minimum bend radius of hydraulic hoses.

In this article, we will delve into what minimum bend radius is, how it's measured, common misconceptions, and why it's crucial to consider in hydraulic hose selection.

What is a Minimum Bend Radius?

The minimum bend radius refers to the smallest diameter a hose can be bent without being kinked or damaged.

It's a critical parameter in hydraulic systems where hoses often need to navigate tight spaces and sharp corners. Exceeding the minimum bend radius can lead to hose failure, compromising the integrity of the entire hydraulic system.

How is it Measured?

Measuring the minimum bend radius involves assessing the distance from the inside edge of the hose to the centerline of the bend.

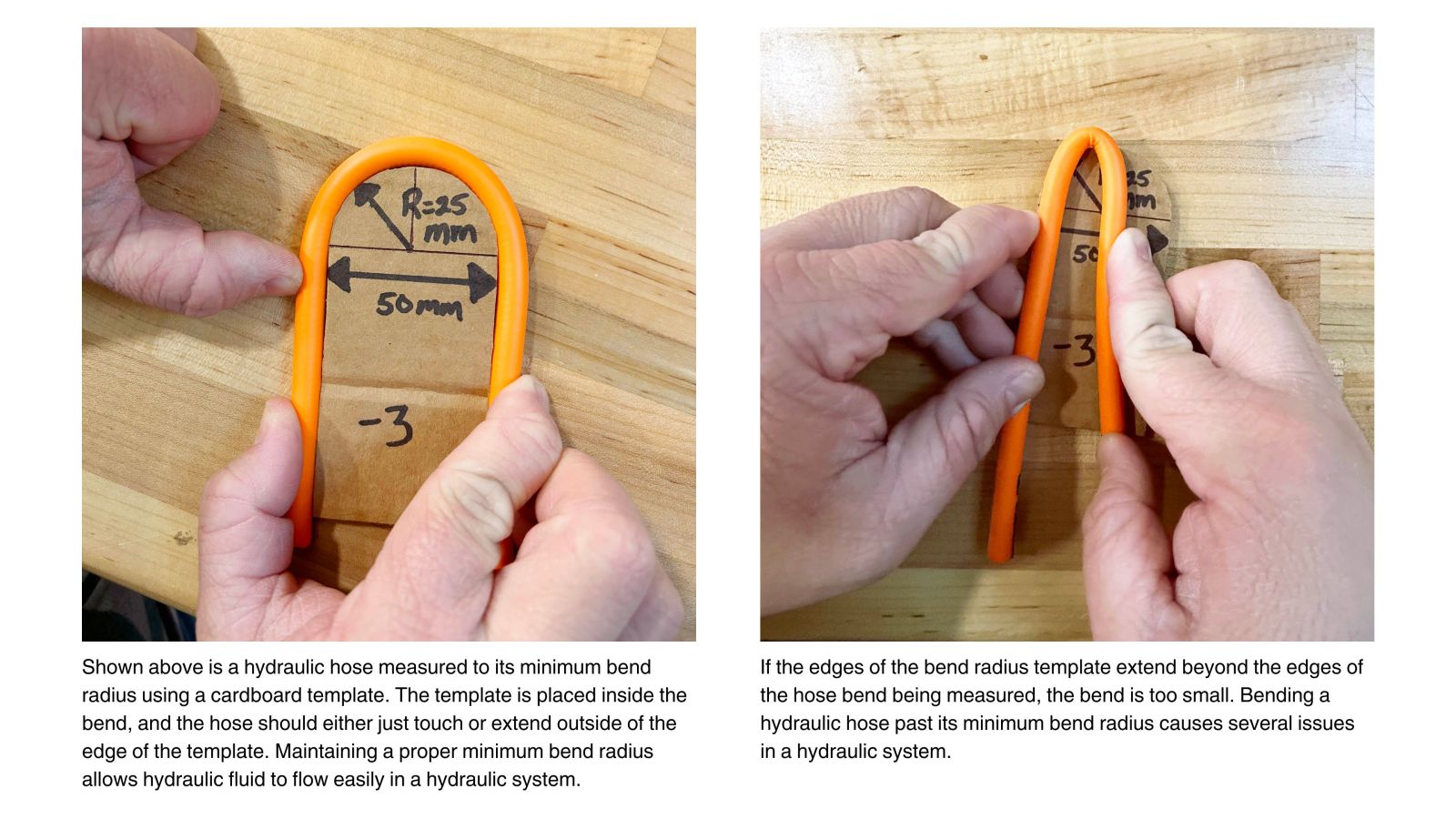

One practical method for checking the bend radius is using a cardboard template cut to the specified radius. By comparing the template to the hose bend, it's easy to determine if the bend meets the required radius or if adjustments are necessary.

Common Misconceptions

One common misconception is assuming that the relationship between flexibility and bend radius is proportional. In reality, the lower the minimum bend radius, the tighter the hose can be bent without damaging the hose.

Additionally, it's erroneous to gauge the bend radius of a hose solely by visual inspection. The hose construction, including the number of layers and the type of reinforcement, significantly influences its bend radius.

Why is Bend Radius Important?

The importance of bend radius cannot be overstated when selecting hydraulic hoses. It dictates the limits of hose flexibility and determines the extent to which hoses can withstand bending without damage. Neglecting to adhere to the minimum bend radius can result in kinks, abrasions, and eventual failure of the hose, leading to costly downtime and repairs.

Bottom Line: Prioritizing Safety and Performance

While it's understandable that hydraulic hose installations may sometimes overlook bend radius requirements due to time or budget constraints, doing so poses significant risks. Regular inspections and adherence to proper installation practices can help identify non-compliant hose assemblies, allowing for timely replacement or adjustment.

Investing in hoses that meet or exceed minimum bend radius specifications not only ensures the safety of operators and maintenance personnel but also enhances the longevity and performance of hydraulic systems.

By prioritizing bend radius considerations during hose selection and installation, industries can mitigate potential hazards and optimize the reliability of their hydraulic equipment.

Download the Measuring Minimum Bend Radius PDF